The Short Answer: Lean certification equips construction professionals with systematic methods to eliminate waste, improve workflow, and boost project efficiency. Through structured training in lean principles and tools, certified teams reduce delays, minimize rework, and increase customer satisfaction while creating a culture of continuous improvement that transforms how construction projects are managed and delivered.

Construction projects face constant pressure to deliver quality results faster and more efficiently than ever before. Delays, rework, and communication breakdowns between trades can turn profitable projects into financial disasters. Lean certification offers construction companies a proven framework to address these challenges by teaching teams how to identify waste, optimize processes, and maintain consistent quality standards. This systematic approach to project management has helped construction firms reduce project timelines while improving both team morale and client relationships.

Understanding Lean in Construction

Lean methodology originated in manufacturing but has transformed construction management over the past two decades. At its core, lean focuses on maximizing value for customers while minimizing waste in every aspect of the construction process. This philosophy shifts the focus from individual productivity to overall project flow, helping teams work smarter rather than harder.

The construction industry presents unique challenges that lean principles address directly. Unlike manufacturing, construction projects involve multiple trades working in sequence, weather dependencies, and site-specific variables that change with each project. Lean methodology adapts to these realities by providing flexible frameworks that improve coordination, reduce waiting times, and eliminate unnecessary movement of materials and workers.

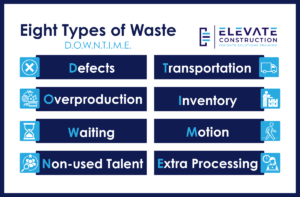

Construction companies implementing lean principles typically focus on eight types of waste:

- Defects: Rework due to errors or quality issues

- Overproduction: Building more than needed or before it’s needed

- Waiting: Idle time between trade activities

- Non-utilized talent: Underusing team members’ skills and knowledge

- Transportation: Unnecessary movement of materials

- Inventory: Excess materials sitting on site

- Motion: Unnecessary movement of workers

- Extra processing: Doing more work than the customer values

What Is Lean Certification?

Lean certification validates an individual’s knowledge and ability to apply lean tools and concepts in real-world situations. These certification programs provide structured learning paths that combine theoretical knowledge with practical application, helping professionals develop skills they can immediately use on construction projects.

The certification process typically involves completing training courses, passing examinations, and demonstrating practical application of lean concepts through project work. Different certification levels reflect varying depths of expertise and responsibility within lean implementation efforts.

Most lean certification programs in construction cover fundamental areas including:

- Value stream mapping for construction processes

- 5S workplace organization techniques

- Pull planning and Last Planner System implementation

- Root cause analysis for construction defects

- Visual management systems for job sites

- Standardized work procedures for repetitive tasks

- Continuous improvement methodologies

Professional certification bodies like Elevate Construction and various training providers offer construction-specific programs that address industry needs. These programs often incorporate case studies from actual construction projects, making the learning directly applicable to participants’ daily work.

Benefits of Lean Certification for Construction Companies

Improved Operational Efficiency

Certified lean practitioners identify and eliminate inefficiencies that plague construction projects. By applying lean tools systematically, teams reduce cycle times, minimize material handling, and optimize work sequences. Projects flow more smoothly when team members understand how their work impacts overall project success.

Enhanced Team Dynamics and Communication

Lean certification programs emphasize collaborative planning and communication techniques. Certified professionals learn to facilitate pull planning sessions, conduct effective daily huddles, and create visual management systems that keep everyone informed. These skills break down silos between trades and create more cohesive project teams.

The structured problem-solving approach taught in certification courses helps teams address issues objectively without blame. This improves morale and encourages workers to identify problems early rather than hiding them until they become critical.

Increased Customer Satisfaction

Lean-certified teams deliver projects that better meet client expectations. By focusing on value from the customer’s perspective, teams eliminate activities that don’t contribute to project goals. Regular check-ins and visual progress tracking keep clients informed and engaged throughout the construction process.

The predictability that comes from lean implementation builds client confidence. When projects consistently meet milestones and quality standards, clients become repeat customers and provide valuable referrals.

Financial Impact on the Bottom Line

Investment in lean certification delivers measurable financial returns through:

- Reduced rework costs: Better quality control prevents expensive corrections

- Lower material costs: Improved planning reduces over-ordering and waste

- Decreased labor costs: Efficient workflows minimize overtime and idle time

- Fewer delays: Better coordination prevents costly schedule extensions

- Reduced insurance claims: Safer, more organized sites have fewer incidents

Construction companies typically see return on their lean training investment within the first certified project through these combined savings.

Implementing Lean Culture in Construction

Starting Your Lean Journey

Successful lean implementation begins with leadership commitment. Company executives must understand lean principles and actively support the transformation process. This includes allocating resources for training, allowing time for improvement activities, and celebrating early wins.

Begin with pilot projects that demonstrate lean’s value:

- Select a manageable project with engaged team members

- Provide white or yellow belt training to all participants

- Apply basic lean tools like Takt Production System

- Document improvements and share results company-wide

- Expand to additional projects based on lessons learned

Choosing the Right Certification Program

Select certification courses that align with your company’s needs and project types. Look for programs that offer:

- Construction-specific content: Generic lean training misses industry nuances

- Flexible delivery options: Online learning combined with hands-on practice

- Experienced instructors: Trainers with actual construction experience

- Ongoing support: Access to resources after certification

- Practical focus: Emphasis on real application over theory

Research training providers carefully. The best programs include case studies from similar projects and provide tools you can immediately implement.

Sustaining Continuous Improvement

Lean certification marks the beginning, not the end, of improvement efforts. Successful companies create structures to sustain momentum:

Regular Improvement Events: Schedule quarterly improvement workshops where teams apply lean tools to specific challenges. These focused sessions generate quick wins while reinforcing lean thinking.

Mentorship Programs: Pair newly certified individuals with experienced practitioners. This accelerates skill development and helps embed lean culture throughout the organization.

Performance Metrics: Track key indicators that reflect lean implementation success:

- Percent Plan Complete (PPC)

- First-time quality rates

- Safety incident frequency

- Schedule variance

- Cost predictability

Recognition Systems: Acknowledge teams and individuals who successfully apply lean concepts. Share success stories in company meetings and newsletters to maintain enthusiasm for continuous improvement.

Common Challenges and How to Overcome Them

Construction companies often face resistance when introducing lean certification programs. Address these challenges proactively:

“We don’t have time for training”

Start with short, focused sessions that deliver immediate value. Online programs allow flexible scheduling around project demands.

“Construction is different from manufacturing”

Choose construction-specific certification programs that use relevant examples and address industry realities.

“Our projects are too unique for standardization”

Lean principles adapt to project variability while improving common processes like planning, quality control, and communication.

“Experienced workers resist change”

Involve senior team members early and recognize their expertise. Show how lean tools make their jobs easier, not harder.

Transform Your Construction Operations with Elevate Construction

Ready to reverse productivity decline and make construction enjoyable again? Elevate Construction specializes in lean training courses designed specifically for construction professionals. Our certification programs address the real challenges faced by superintendents, project managers, and field teams, using proven lean tools that deliver measurable results.

We don’t offer generic corporate training. Our construction-focused approach combines lean methodology with practical field applications, helping your teams eliminate waste, improve coordination, and deliver projects on time and within budget.

Take your construction operations to new heights. Contact Elevate Construction today to learn how our lean certification programs can transform your project outcomes, boost team morale, and strengthen your bottom line. Let’s build excellence together.