I am currently writing the second version of Takt Planning & integrated control book and just finished the draft of the section suggesting what books every Superintendent should read. I decided to post this on our blog for anyone who wants to get a head start on the list. Enjoy!

The books listed below have been instrumental to me in my career as a Superintendent. I hope you will find this useful in your career as you select the books you may want to read in your career to take your next step:

High-Performance Habits: How Extraordinary People Become That Way by Brendon Burchard:

In this book, Brendan Burchard explains the six high-performance habits that effective leaders must master to succeed. If you struggle with clarity, energy, necessity, productivity, influence, or courage, I highly recommend you pick up this book.

Leadership and Self-Deception: Getting Out of the Box by The Arbinger Institute:

Every superintendent should read this book. In this work, you will learn how to “get out of the box.” That is a saying that describes how we can leave the metaphorical box of self-deception that we allow when we become triggered, assume negative intent, and engage in unhealthy interpersonal interactions. This book provides guidance for breaking that pattern and re-framing every difficult situation so that we can do the right thing and remain in control of our emotions.

How to Win Friends and Influence People by Dale Carnegie:

This book will help you develop your interpersonal skills. It was initially written as a lecture series about how to deal with people. It is well written, with illustrative stories in every section. Many have found this book life-changing and immediately implementable, and we hope you will too.

The Speed of Trust: The One Thing that Changes Everything by Stephen R. Covey, et al.:

Have you ever wondered what it takes for someone to trust you? Would you like to know? Character and competence. A person must know your intentions, character, track record, and abilities. Stephen R. Covey outlines a pattern of behavior for us that we can use to build trust, which is the first step in team building.

It’s Your Ship: Management Techniques from the Best Damn Ship in the Navy by Captain D. Michael Abrashoff:

In this wonderful read, Captain D. Michael Abrashoff takes you through the story of leading the crew on the USS Benfold. I think superintendents should read this because it showcases the ownership, creativity, and high standards any leader can have when directing their project or ship.

Extreme Ownership: How U.S. Navy SEALs Lead and Win by Jocko Willink and Leif Babin:

If you have ever struggled with any form of a victim mentality, consider reading this book. Jocko Willink provides examples from his experience on deployment about how to be accountable, own the mission, and move forward as a competent team leader.

The Goal: A Process of Ongoing Improvement by Eliyahu M. Goldratt:

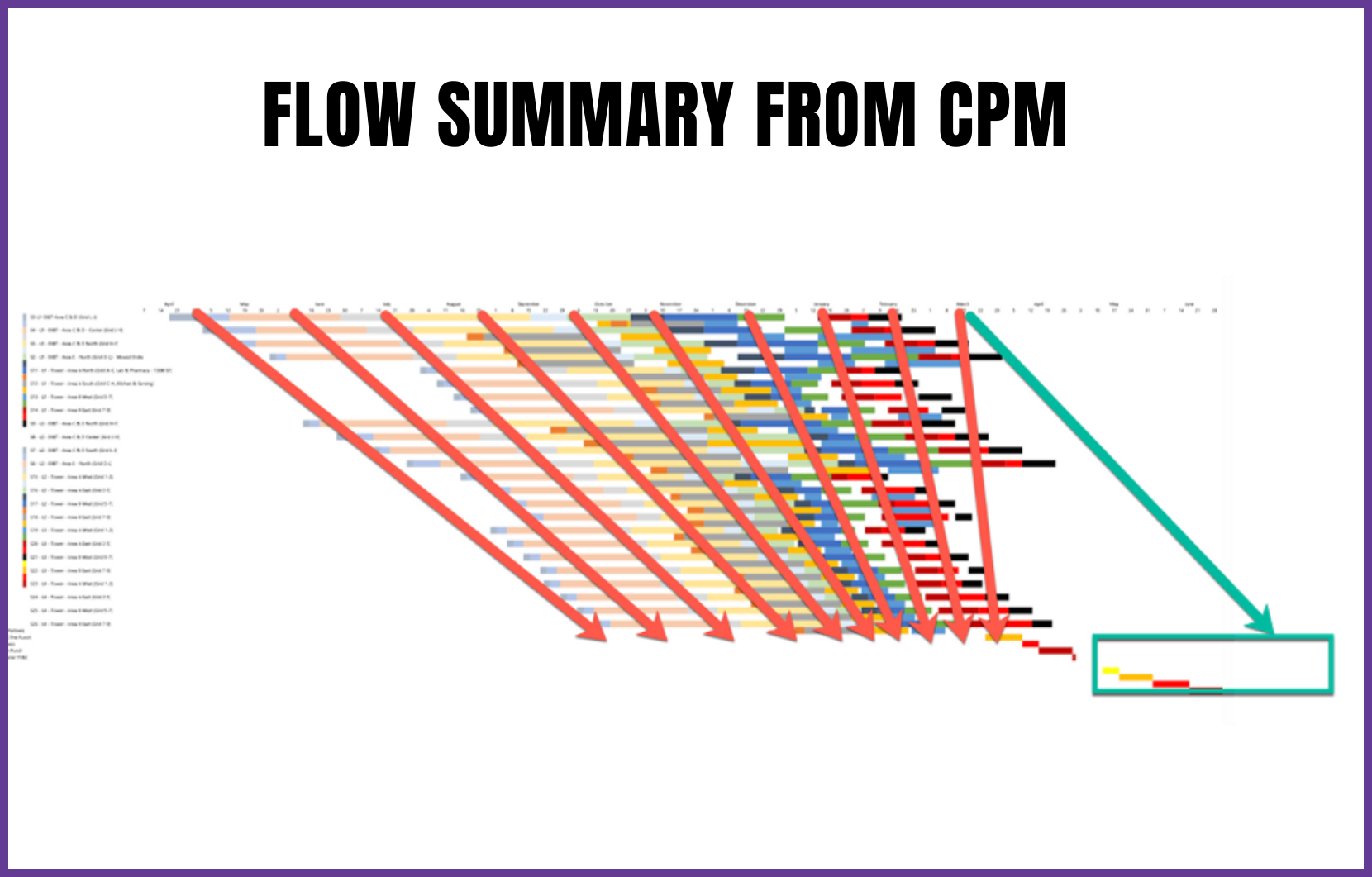

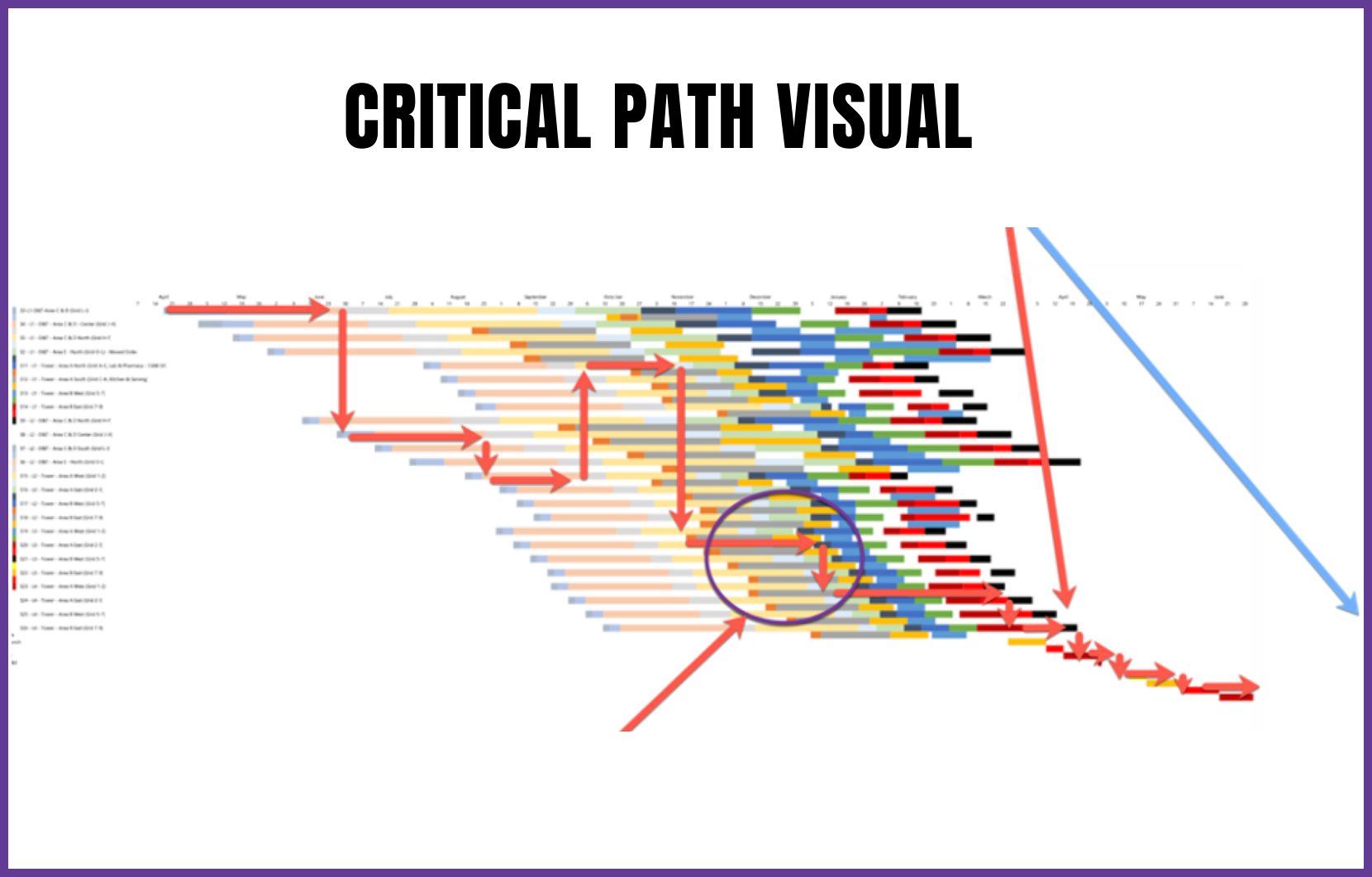

This book provides the basis for creating flow in manufacturing and must be translated to construction so we can focus on flow.

The Bottleneck Rules: The Go-To Guide to Eli Goldratt’s Theory of Constraints (TOC) and his Business Novel ‘The Goal’ (Theory of Constraints Simplified) by Clarke Ching:

This book does a nice job of simplifying the novel “The Goal.” It discusses in detail how to identify and optimize bottlenecks on a project.

This is Lean: Resolving the Efficiency Paradox by Niklas Modig and Par Ahlstrom:

This is the best book about lean and lean concepts on the market. Every superintendent in our industry, and every person for that matter, should read this book.

Toyota Production System: Beyond Large-scale Production by Taiichi Ohno:

If a superintendent wants to understand the foundations of lean and the difference between flow and pull, this book is a must-read.

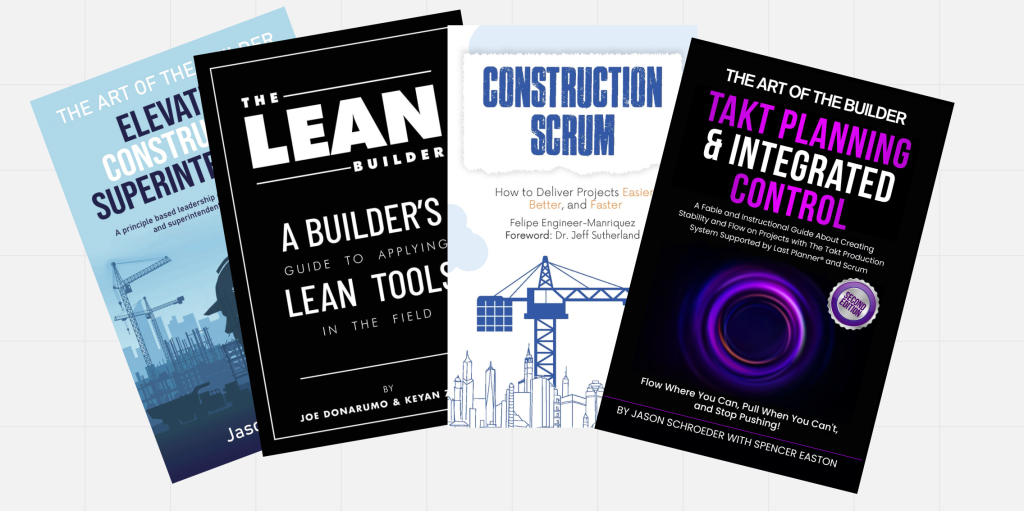

The Lean Builder: A Builder’s Guide to Applying Lean Tools in the Field by Joe Donarumo and Keyan Zandy:

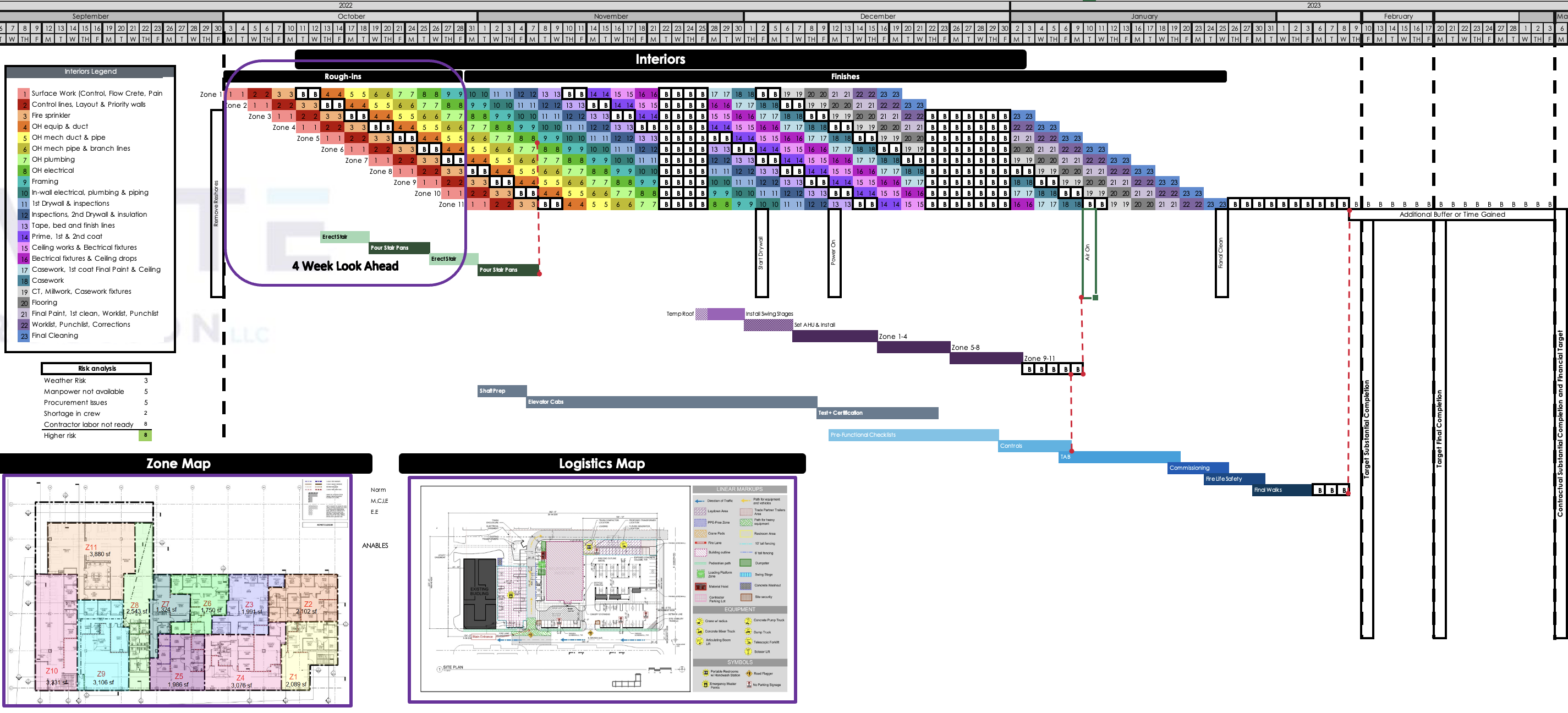

This excellent book summarizes how to implement the Last Planner® system in construction.

Scrum: The Art of Doing Twice the Work in Half the Time by Jeff and J.J. Sutherland:

This is an exceptional book summarizing how to implement Scrum as a scheduling system.

2 Second Lean: How to Grow People and Build a Fun Lean Culture by Paul A. Akers:

In 2 Second Lean, Paul Akers teaches the process of implementing lean principles that have worked for him in his manufacturing facility. The concepts do not tie exactly to construction but can be applied to any leadership situation. He leads the reader through the process of creating a lean culture of excellence. He simplifies it so that anyone can understand and does it in an interesting and abbreviated form. We recommend everyone study this book a few times to be sure to absorb the message.

Elevating Construction Superintendents: A Principle Based Leadership Guide for Assistant Supers and Superintendents in Construction (The Art of The Builder) by Jason Schroeder:

This is fundamental to understanding how a superintendent can approach their role in construction.

Takt Planning & Integrated Control: A Fable and Instructional Guide about Creating Stability and Flow on Projects with The Takt Production System Supported by Last Planner® and Scrum by Jason Schroeder with Spencer Easton:

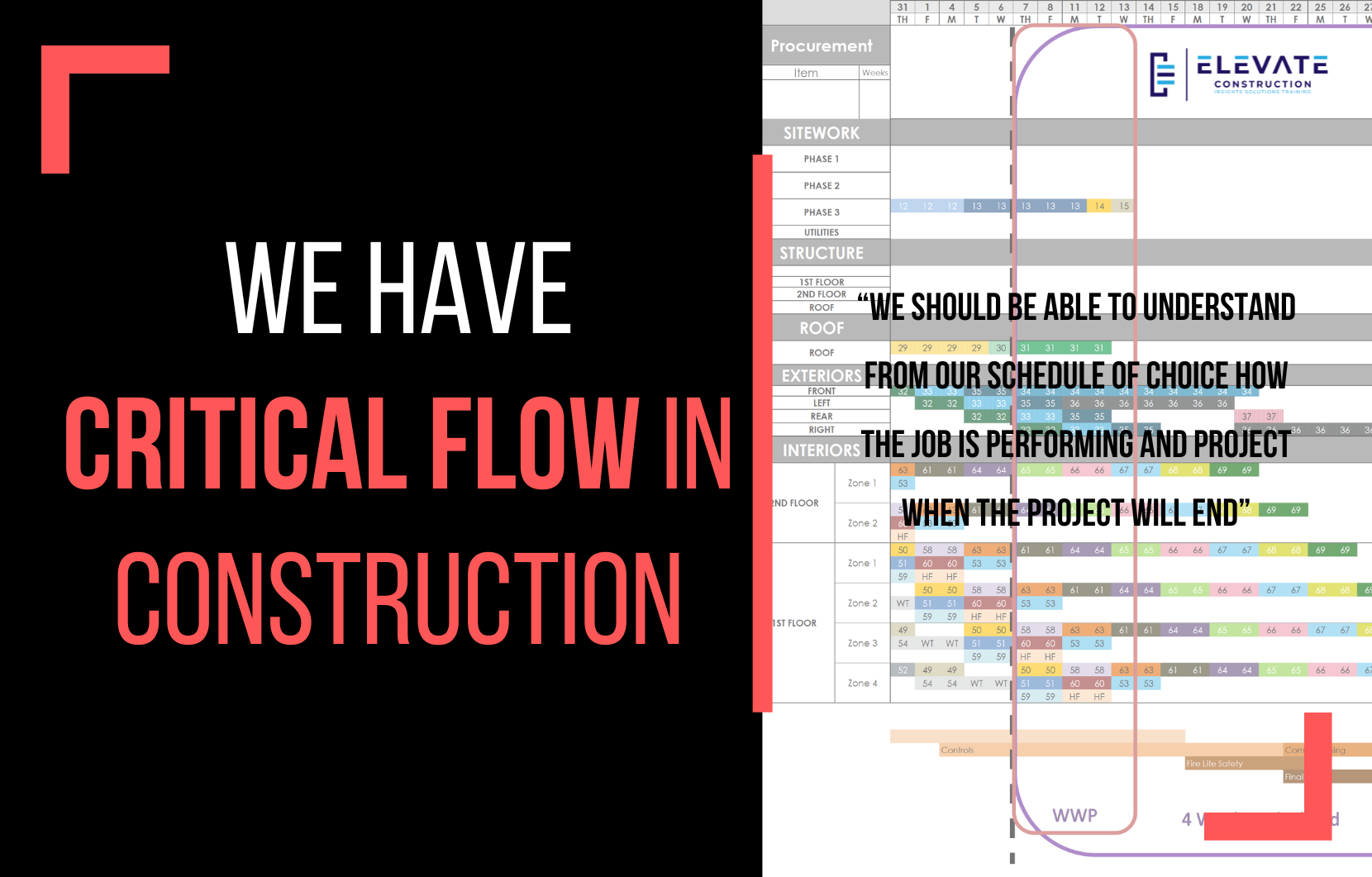

CPM is not the best scheduling method in construction. This book outlines how to create, implement, and use Takt planning in construction as the master scheduling system.

Multipliers, Revised and Updated: How the Best Leaders Make Everyone Smarter by Liz Wiseman, John Meagher, et al.:

This is a must for a leader focused on becoming better at their job. There are multipliers and diminishers in this world. Diminishers don’t believe in people and micromanage. Multipliers believe in people and multiply their efforts!

Mindset: The New Psychology of Success by Carol Dweck:

This is likely the most important book of the century. It outlines the difference between a growth and fixed mindset. Every leader should read this book so they can adopt a growth mindset and really thrive in their career.

Essentialism: The Disciplined Pursuit of Less by Greg McKeown:

This book is crucial for leaders that feel overwhelmed. A Senior Super must focus on what is essential, and this book will help with that focus.

How to Stop Worrying and Start Living by Dale Carnegie:

In How to Stop Worrying and Start Living, Dale Carnegie again provides advice that has no equal in the form of how to reduce stress and worry. For those who tend to suffer from stress and anxiety, the practical steps he lists in the book can make the difference between a happy and productive life and one of constant misery.

The Upside of Stress: Why Stress Is Good for You, and How to Get Good at It by Kelly McGonigal:

There is good stress and bad stress. This book will help any leader identify the difference and move as much of the pressure as possible from the stressful category to the helpful.

The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and Organizing by Marie Kondo.

In this book, Marie Kondo explains the Japanese philosophy of practicing cleanliness and organization in an effort to strive for perfection. It is hard for people to understand the need for cleanliness on projects in this industry. That is because we are all conditioned to mediocrity. With her passionate approach to tidying, Kondo can inspire the reader to reach for perfection and joy in cleaning. Everything on-site should bring joy to the workers, owners, and management team. She will show you how.

33 Strategies of War by Robert Greene:

As a superintendent, I really appreciated this book about military strategy. However, some chapters do not apply—for instance, the chapters about espionage. If a Super reads this with a selective eye, they will glean wisdom from indispensable history.

The Art of War by Sun Tzu:

Everyone knows this is a classic for any leader interested in logistics, strategy, and tactics.

The Motive: Why So Many Leaders Abdicate Their Most Important Responsibilities by Patrick Lencioni:

This book is remarkably clear about what leaders should focus on so they do not abdicate what only a leader can and should do.

The Five Dysfunctions of a Team: A Leadership Fable by Patrick Lencioni:

This book is essential for anyone who is part of a team or leads one. Every team will struggle if they do not apply the principles of building trust and employing healthy conflict. It’s hard to believe, but the answer to how we can be a good team is simple and contained in this book.

Death by Meeting: A Leadership Fable…About Solving the Most Painful Problem in Business by Patrick M. Lencioni:

This book will help any leader to run a remarkable meeting.

The Advantage: Why Organizational Health Trumps Everything Else In Business by Patrick M. Lencioni:

This book shows how scaling communication is key to any leadership position and team.

The Truth About Employee Engagement: A Fable About Addressing the Three Root Causes of Job Misery by Patrick M. Lencioni:

This book will help you as a leader to be a good manager and create engagement with your direct reports.

The Ideal Team Player: How to Recognize and Cultivate the Three Essential Virtues by Patrick M. Lencioni:

The Ideal Team Player describes, in the form of a fictional story, the attributes needed to be a good team player. Patrick Lencioni demonstrates the need to be humble, hungry, and smart. You may think you know what those words mean, but there is much more to each of them than what initially comes to mind. The book’s message is helpful, insightful, and life-changing if applied.

The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer by Jeffrey Liker:

The 14 principles in this book are crucial to lean construction implementations. Jeffrey outlines the key principles that will support and benefit any construction project.

The Leader Who Had No Title: A Modern Fable on Real Success in Business and in Life by Robin Sharma:

This book is a little corny, but it clearly identifies in a simple manner what steps each leader should take to give and develop influence.

The Go-giver: A Little Story About a Powerful Business Idea by John David Mann & Bob Burg:

This book changed my life. Every leader must focus on giving to be ultimately successful. This book will help change your perspective so you can provide more and lead the way you want.

Switch: How to Change Things When Change is Hard by Chip and Dan Heath:

Switch was written to help people with implementation. If you have already learned the art of dealing with people, the next step is to find safe and effective ways to lead individuals and groups through the process of change. The authors take the reader through a thought-provoking analogy of the Rider, the Elephant, and the Path. The Rider is our intellect, the Elephant is our motivation, and the Path represents our circumstances when trying to change. All three must work together. Chip and Dan Heath provide practical steps to help us implement change when it becomes hard. The book is important because it will allow builders to become adept at implementing change on projects. Without this practical knowledge, it can be easy to fall victim to unavoidable circumstances.

The Captain Class: The Hidden Force That Creates the World’s Greatest Teams by Sam Walker:

This book shows how any leader can support and enable their team for optimum performance.

I hope you enjoy these books as I have. If you don’t like reading actual books, consider Kindle. If that does not work for you, consider Audible. If Audible does not work for you, a service called Blinkist summarizes these books for you into Blinks that total around ten minutes of listening time.